# Advancements in Stretchable Electronics: The Future of Wearable Tech

Written on

Chapter 1: The Promise of Stretchable Electronics

Stretchable electronics hold immense potential across various sectors, including healthcare, where they can revolutionize wearable sensors and implantable devices. These innovations also extend to robotics and consumer electronics, such as flexible displays and touchscreens. The ongoing research in this field focuses on enhancing materials and fabrication methods to boost performance and broaden application possibilities.

An international research team from Nanyang Technological University (NTU) in Singapore, in collaboration with experts from Stanford University, Shenzhen Institute of Advanced Technology, and A*STAR, has made significant strides in this area. They have engineered a versatile connector for stretchable devices that enables quick and easy assembly, akin to the simplicity of building with Lego bricks.

Devices like soft robots and wearable health technologies consist of various modules, each with unique material characteristics, including soft, rigid, and encapsulated components. Traditional adhesives used to connect these modules often fail to reliably transmit mechanical and electrical signals during deformation, necessitating custom connectors that can withstand the required stresses.

Section 1.1: The BIND Interface Revolution

Any electronic module equipped with the BIND interface can be connected effortlessly by pressing them together for less than ten seconds. This innovation eliminates the tedious need for customized interfaces tailored to specific systems, potentially accelerating the development of stretchable devices.

> "Our approach simplifies the assembly of these devices, making it much more efficient," stated Chen Xiaodong, the lead author of the study.

Subsection 1.1.1: BIND's Exceptional Performance

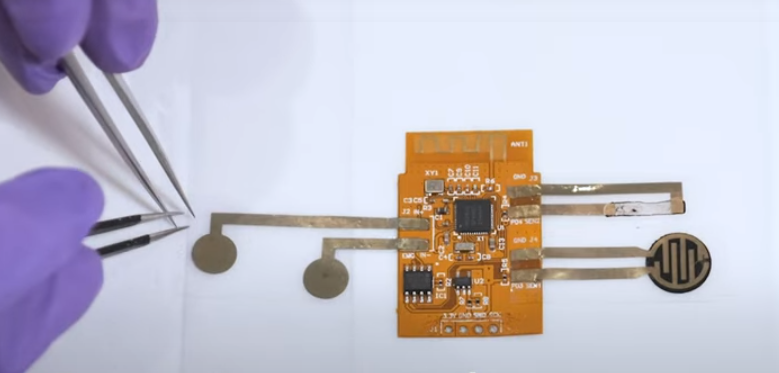

The newly developed biphasic, nano-dispersed interface (BIND) boasts remarkable mechanical and electrical performance, allowing for easy assembly of high-performance stretchable devices simply by pressing together any module featuring the BIND interface. This design permits seamless integration of components according to the producers' specifications.

Researchers created the BIND interface by thermally evaporating metal nanoparticles, like gold or silver, to form a durable interpenetrating nanostructure within a commonly used thermoplastic for stretchable electronics—specifically, styrene-ethylene-butylene-styrene. This nanostructure ensures continuous mechanical and electrical pathways, enabling modules connected via BIND interfaces to retain their strength even when deformed.

The interface modules assembled with the BIND connector displayed impressive durability during stretching tests, surviving elongation up to seven times their original length before failure. Electrical signal transmission remained stable even when stretched to 2.8 times the original length. Additionally, the interfacial toughness was found to be 60 times stronger than that of traditional connectors.

Section 1.2: Applications in Health Monitoring

A wearable skin patch designed to monitor multiple health conditions comfortably adheres to the skin, providing vital information regarding life-threatening health issues.

Stretchable devices featuring the BIND interface have undergone testing on rat models and human skin, demonstrating consistent signal quality and high-quality electromyography (EMG) signals that accurately measure muscle activity, even in underwater conditions.

In light of these breakthroughs, an international patent application for the BIND interface innovation has been submitted. The research team is now concentrating on developing more efficient printing technologies to expand the range of materials and applications for this groundbreaking innovation, aiming to expedite the transition from laboratory development to commercial product design and manufacturing.

Chapter 2: Looking Ahead

The first video, How to Use and Maintain a Juki Industrial Sewing Machine, delves into the operational intricacies and maintenance tips for this essential industrial tool.

The second video, How To Use The Brother BQ2500 Sewing & Quilting Machine!, offers a comprehensive guide on utilizing this sewing and quilting machine effectively.

The complete research findings were published in the Journal of Nature.

Stay updated with more stories like this from Faisal Khan on Medium, and consider joining my mailing list to receive essential content directly.