Unlocking Productivity: Overcoming the Blindspot in Knowledge Work

Written on

Author’s Note: This piece emerged from over 60 hours of dedicated effort, utilizing the blockbuster mental model. If you appreciate this writing style and wish to craft compelling viral content, subscribe to my Blockbuster Blueprint newsletter for three detailed articles each week.

This article is part of a comprehensive series on productivity, developed over hundreds of hours of research guided by the blockbuster philosophy. Here are the other articles in the series:

- How a 1911 Genius Revealed a Forgotten Science to Boost Productivity 50x

- The Productivity Crisis: Insights from 52 Years of Data

- The Harsh Reality of Overlooked Life-Changing Opportunities

Now, back to the topic at hand…

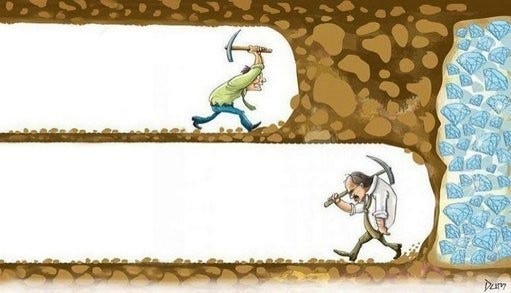

As I delve deeper into productivity's history, it becomes increasingly clear that we struggle with effective productivity. Consequently, the image below resonates as a stark truth rather than a lighthearted joke.

Many of us envision ourselves as the individual confidently demonstrating wheelbarrow usage.

However, the reality may be quite different.

We often find ourselves hustling with the latest tools (like a wheelbarrow) and can’t imagine being significantly more productive, especially when we’re already exerting so much effort.

Yet…

There exists a critical blindspot that hampers our ability to utilize the metaphorical wheelbarrow effectively. This isn't our fault, but until we identify this blindspot, our potential remains constrained.

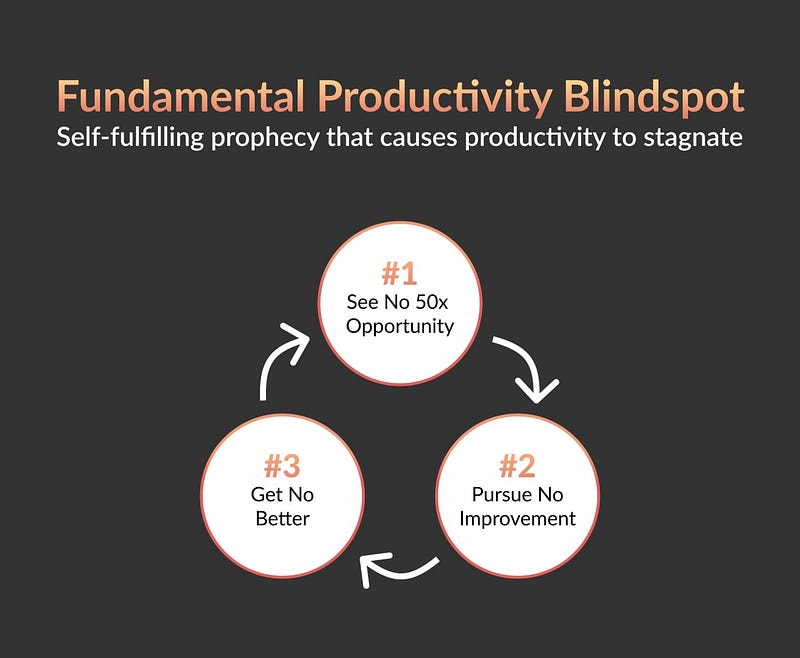

The Core Productivity Blindspot: Ignoring Improvement Opportunities

The Core Productivity Blindspot creates a damaging cycle where:

- We fail to recognize the vast improvement opportunities available daily.

- Consequently, we invest little time in focused, ongoing improvement.

- This lack of progress reinforces our belief that improvement is unnecessary.

The illustration below depicts this cycle…

Due to this blindspot ingrained in modern work culture, we experience the following five symptoms:

- We underestimate our capacity for improvement.

- We overestimate our daily productivity.

- We fail to recognize our actual unproductiveness.

- We overlook the significant benefits of continuous improvement, as compounding can be difficult to grasp.

- We lack a clear understanding of deliberate, systematic improvement, leading us to settle for less.

Understanding each symptom is crucial to grasp the full impact of the Core Productivity Blindspot…

Symptom 1: Underestimating Our Improvement Potential

In The Harsh Reality of Overlooked Opportunities, I provide numerous historical examples illustrating how we have overlooked essential technologies for centuries, often due to our inability to see them. This challenges the common belief that significant innovations are always recognized and developed promptly.

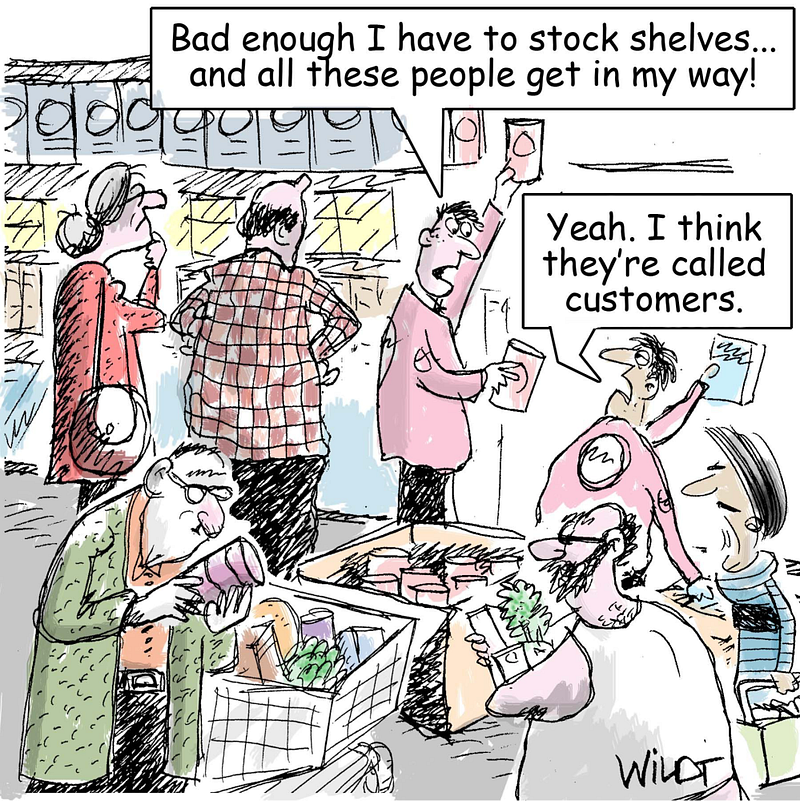

Symptom 2: Overestimating Daily Productivity

Daily, various factors mislead us into believing we are productive even when we are not:

- We check off tasks from our to-do lists.

- We work diligently.

- We feel productive.

- We compare ourselves to average productivity levels rather than our potential.

These factors often lead us to conflate busywork with genuine productivity, much like the cartoon illustrated below:

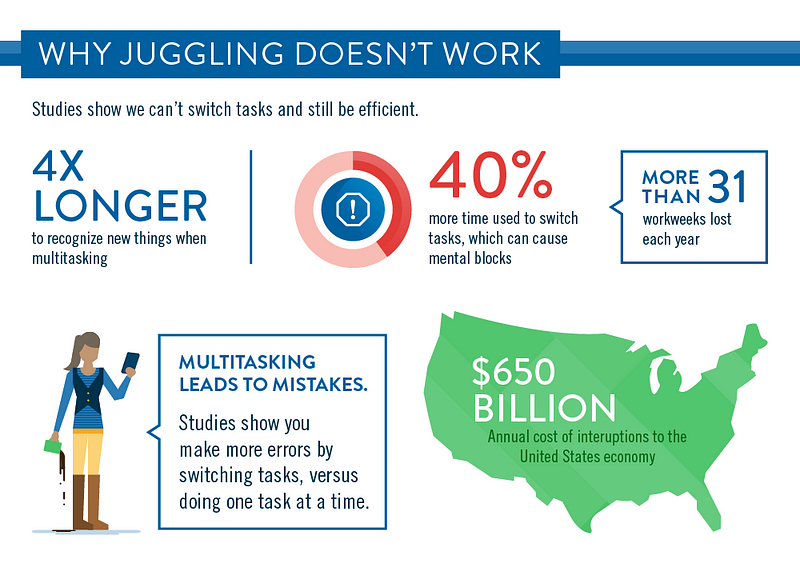

Symptom 3: Underestimating Our Unproductiveness

“Waste” that undermines our productivity often remains hidden.

For instance, research cited by Cal Newport in A World Without Email shows that the average knowledge worker is interrupted every 20 minutes by notifications.

Each interruption incurs costs:

- It typically takes 10–15 minutes to regain focus.

- Mistakes become more frequent.

- We lose precious time for deep focus, which is already scarce.

These costs accumulate throughout the day, but we often overlook their total impact, as shown in the infographic below:

Symptom 4: Underestimating Continuous Improvement

“Understanding both the power of compound interest and the difficulty of achieving it is crucial to grasping many concepts.” — Charlie Munger, Long-Time Partner of Warren Buffett

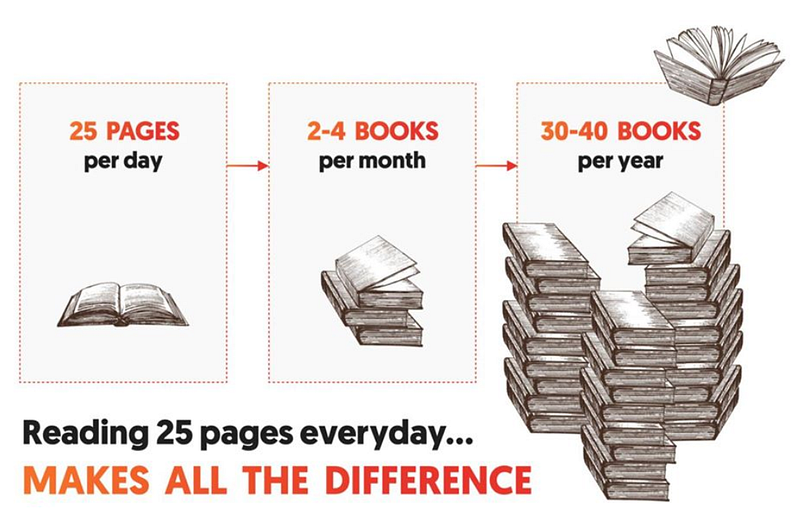

The image below vividly illustrates the benefits of small, incremental improvements…

Reading just 25 pages daily might not seem substantial, but it enables us to read 30–40 books a year, fostering real expertise in new areas and enhancing our job performance.

Symptom 5: Misunderstanding Deliberate Improvement

Many today proudly identify as lifelong learners, often because they enjoy learning and strive for improvement. They follow insightful individuals on social media, read industry publications, and consume a few books annually, feeling accomplished.

However, after studying and teaching how to learn effectively along with productivity history, it’s become clear that what many label as lifelong learning is better described as hobby learning (and sometimes even junk learning).

I remember contrasting the mindset of hobbyists versus professionals firsthand during my competitive tennis days. While I could outplay most at my level, facing top-ranked opponents revealed the intensity of their training. They practiced extensively, received daily coaching, and had support to maintain their fitness. In contrast, I rarely encountered their level of commitment.

This same disparity occurs in learning. We often overrate our abilities, oblivious to the levels above us…

Few individuals consistently allocate substantial time for learning. Even fewer prioritize learning how to learn more effectively.

Moreover, most lack the foundational frameworks for productivity improvement that have proven successful throughout history. More on these frameworks later.

Summary: The Core Productivity Blindspot in contemporary work culture leads to the following symptoms:

- Underestimating our improvement potential.

- Overestimating daily productivity.

- Underestimating daily unproductiveness.

- Overlooking the value of continuous improvement.

- Misunderstanding the essence of systematic improvement, leading to complacency.

Consequently, we find ourselves in a self-fulfilling cycle:

- We miss out on visible improvement opportunities.

- We fail to invest sufficient time and effort into improvement.

- This lack of investment results in stagnation.

Implication: The Core Productivity Blindspot has detrimental effects and may significantly contribute to the silent productivity crisis we've experienced over the past 52 years.

Fortunately, there's encouraging news…

Given how low the current standards are, I believe the average knowledge worker can achieve 50x greater productivity over their lifetime if they intentionally set aside time for improvement and enhance their improvement methods.

My confidence in the potential for a 50x increase stems from hundreds of hours studying the remarkable productivity growth of the 20th century, much of which has been forgotten. Here’s the historical perspective you may not have considered…

Lessons from History: Achieving 50x Productivity

“The unique contribution of management in the 20th century was the fifty-fold increase in productivity among manual workers in manufacturing.” — Peter Drucker, Pioneer of Management Studies

Astounding, isn’t it?

When I first encountered that quote, I was incredulous. A 50x productivity boost for the average worker seemed like a mistake. I had to dig deeper…

I embarked on an extensive investigation to comprehend the reasons behind the productivity surge from 1870 to 1970. I initially thought it would be a quick discovery, but 100 hours later, I published How a 1911 Genius Revealed a Forgotten Science to Boost Productivity 50x. That 100 hours turned into hundreds, and one article morphed into a series.

Through this process, I gained invaluable insights into why the productivity of manual workers soared by 50x. The ultimate conclusion aligns with Peter Drucker’s observations:

“After Frederick Winslow Taylor analyzed work methods, the productivity of manual workers began an unprecedented rise… This achievement underpins all the economic and social advancements of the 20th century.” — Peter Drucker

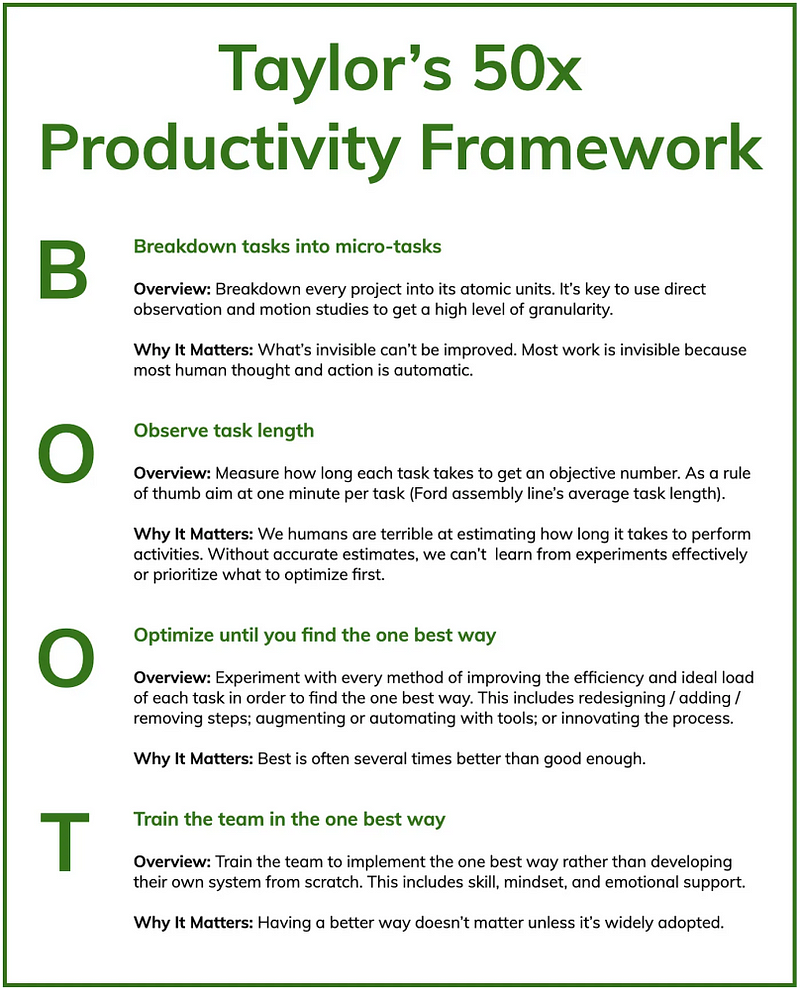

To summarize Taylor’s productivity improvement system, he:

- Deconstructed each production step into one-minute tasks.

- Analyzed these tasks in detail (time and motion tracking).

- Systematically experimented to discover the optimal methods.

- Standardized these methods across the workforce.

I developed the following cheat sheet for an overview (full explanation here):

While this 50x productivity framework may appear simple, it is profoundly effective. It rests on three timeless principles that have driven productivity improvement for ages: specialization, continuous improvement through experimentation, and standardization.

Timeless Principle 1: Specialization

Instead of having one individual tackle 30 different tasks, allow them to concentrate on one task repeatedly. This straightforward insight proves powerful, as it means workers:

- Require less training.

- Maintain focus due to reduced task-switching.

- Complete more work.

- Make fewer errors.

- Improve more rapidly.

Thanks to specialization on assembly lines, intricate craft skills once requiring years of training were replaced by unskilled workers mastering their one-minute tasks in mere hours, completing over 500 practice repetitions daily.

To grasp the impact of specialization, consider the opening page of economist Adam Smith’s seminal work, The Wealth of Nations. In a pin factory, just 10 workers can produce an astonishing 48,000 pins daily due to labor division, where each person specializes in a specific task. Smith estimated that if each worker handled every step individually, they would collectively produce only 200 pins a day. In essence, specialization enhances productivity by 240x.

Interestingly, renowned investor Warren Buffett regards specialization (or his term, circle of competence) as a crucial principle in making sound investment decisions. He only invests in a select few companies where he possesses a comparative advantage in assessing their value. While we may not be investing billions like Buffett, we constantly make decisions about where to allocate our time and resources.

Bottom line: Despite many knowledge workers viewing themselves as specialists, they often operate as generalists compared to the world’s top manufacturers.

Timeless Principle 2: Continuous Improvement Through Experimentation

“If you are going to pursue continuous improvement, you must recognize that things are often chaotic.” — Taiichi Ohno, Creator of the Toyota Production System

“To eliminate waste, one must first recognize its presence and consider how to mitigate it.” — Taiichi Ohno

Rather than relying on informal best practices, Taylor employed a scientific approach to continually experiment until he identified the most effective methods. This frequently resulted in significant productivity gains for tasks, even those long-established without improvement.

For example, in How a 1911 Genius Revealed a Forgotten Science to Boost Productivity 50x, I recount how Taylor doubled productivity in the age-old and simple task of shoveling:

“In 1898, Taylor was commissioned by Bethlehem Steel to enhance the productivity of its 600 shovelers. He sought to establish a science of shoveling.

He began by questioning basic assumptions: ‘What is the optimal shovel load for a top-tier shoveler? Would a first-class worker perform better with a 5, 10, 15, 20, 25, 30, or 40-pound load?’”

He then conducted time and motion studies alongside experiments on:

- Types of shovels (settling on 8–10)

- Shoveling methods (testing different distances, weights, and heights)

- Management systems (training employees in the scientific method to conduct experiments, standardizing effective practices across the company, and incentivizing individuals rather than offering a collective wage).

After extensive experimentation, he concluded that the ideal shovel load was 21 pounds.”

Bottom line: If a simple task like shoveling can be improved twofold, consider the potential for enhancing more complex knowledge work activities.

Timeless Principle 3: Standardization

“Without standards, there can be no continuous improvement.” — Taiichi Ohno

Taiichi Ohno, the Toyota executive responsible for transforming the former textile company into a leading automaker, is also known as the father of lean production.

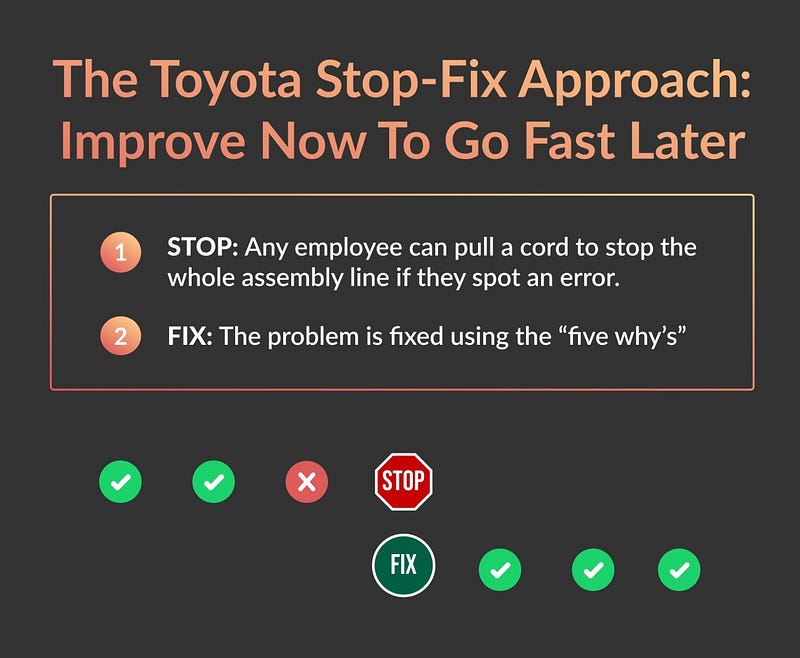

One of his most impactful innovations was the Stop-Fix approach, which worked as follows:

- Establish a quality standard.

- Train all employees to meet that standard.

- If a deviation from the standard occurs, any employee can halt the assembly line by pulling a cord at their workstation. This was unprecedented at the time.

- Management and employees collaborate to identify the root cause using the five whys method, asking “Why did this occur?” five times until the underlying issue is revealed.

- Once resolved, the assembly line resumes.

Here’s a simplified visual overview of this method:

This policy is remarkable considering its potential costs. A halted assembly line can disrupt everything, from parts delivery to finished product shipping. Furthermore, employees on the line are left idle until the issue is resolved.

Surprisingly, this approach proved remarkably effective.

James Womack, author of The Machine That Changed The World, details its success:

- Initially, the assembly line frequently halted.

- Workers felt disheartened.

- However, over time, the rate of errors dropped significantly.

- While the line initially stopped more than traditional mass production lines, it ultimately experienced fewer stoppages.

- Today, this system yields a notably higher output.

- The amount of rework required before shipment consistently declined.

- The quality of shipped vehicles steadily improved.

Bottom line: Through the counterintuitive yet effective Stop-Fix practice, both productivity and quality improved dramatically. A key factor in this success was having a clear quality standard that was monitored and enforced. Most knowledge workers lack such standards and often miss signals indicating unproductive practices.

Side Note: Many associate standardization with companies rigidly enforcing outdated practices. However, Ohno’s quote illustrates that standards can be dynamic:

“There is something called standard work, but standards should be evolving constantly… The standard serves merely as a baseline for further improvement.” — Taiichi Ohno

This Raises an Important Question…

While principles of specialization, continuous improvement through experimentation, and standardization have been applied for ages, the 20th century pushed these concepts to their limits.

Frederick Taylor was just the beginning. Building on his success, manufacturers of the 20th century innovated further (assembly line, lean methodologies, agile practices, six sigma, total quality management, etc.). Over time, the manufacturing sector gained an almost unimaginable capacity to produce complex items (e.g., smartphones) for billions of consumers with minimal error rates at remarkably low costs. It’s astonishing how a $30 electronic device with hundreds of components can be delivered to your doorstep the day after ordering it online, and we often take this for granted.

The more I explored Taylor’s methods and the subsequent productivity movement, the more I pondered a challenging question…

Why aren’t we simply replicating past successes and applying them to knowledge work?

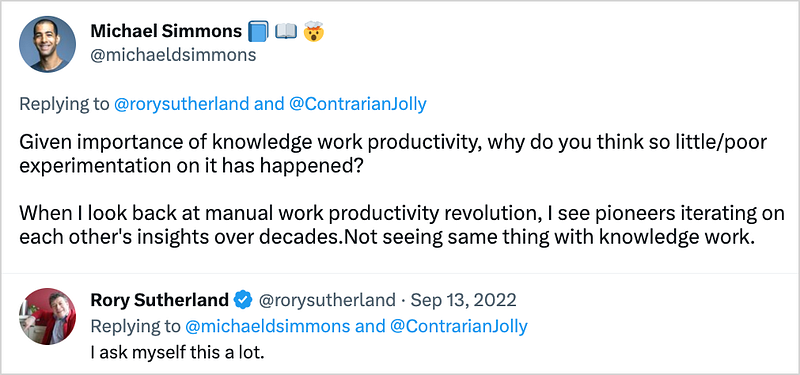

I’m not alone in this inquiry. Below is a conversation I had on Twitter with Rory Sutherland, bestselling author and vice-chair of the Ogilvy Group, one of the largest advertising agencies globally:

The Disheartening Reality: Ignoring Historical Lessons

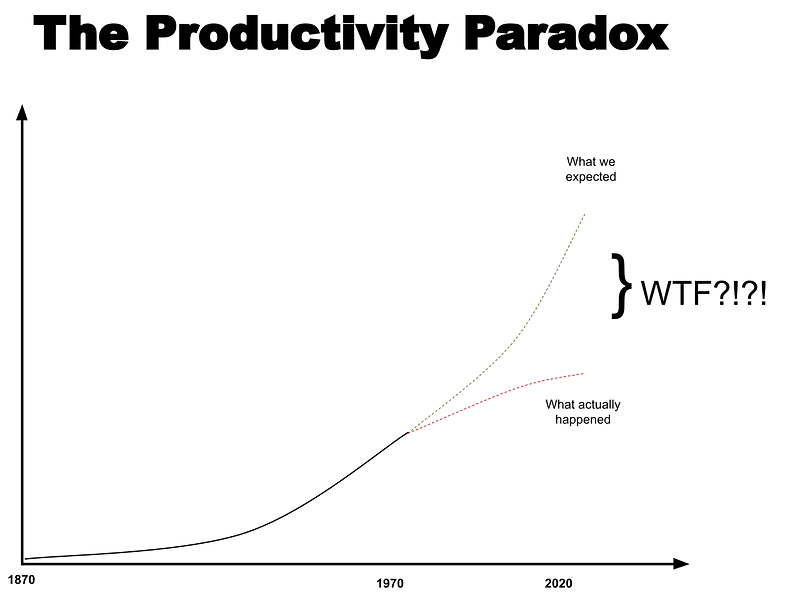

Around 1970, following nearly a century of remarkable productivity growth among manual laborers, something unusual occurred.

At the very moment productivity should have skyrocketed due to computers and the Internet, it stagnated. This phenomenon is known as the Productivity Paradox:

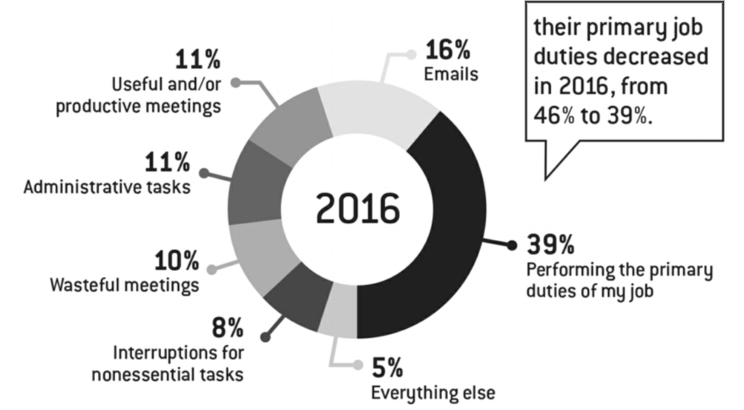

Additionally, another odd trend emerged. After over a century of remarkable results from specialization, experimentation, and standardization, we seemed to abandon many of these principles during the transition to knowledge work. The more I researched, the more it felt like we were not just stagnant but regressing in their application. I questioned…

- Why have we shifted toward generalism? Why are so many knowledge workers juggling meetings, messages, various software tools, and their primary responsibilities? The survey illustrating how employees allocate their time conveys the message clearly:

- Why is there so little experimentation? Why aren’t we thoroughly scrutinizing every task within companies and relentlessly seeking improvements?

- Why are organizations investing less in training instead of more? In today’s work environment, most employees are expected to navigate challenges independently, leading them to develop their productivity systems haphazardly without rigor.

The Significant Opportunity

The Productivity Paradox was so perplexing that Peter Drucker challenged our generation:

“The primary responsibility of management in the 21st century is to enhance productivity among knowledge workers.” — Peter Drucker

Having explored productivity extensively, I feel optimistic about our ability to meet Drucker’s challenge.

Firstly, with significant shifts, conditions often worsen before they improve. This holds true for knowledge work as well.

We are at the onset of the largest transition in human history—the shift to digital knowledge work. We’re still in a formative phase, attempting to reinvent everything rather than learning from historical successes. Eventually, we will begin to heed the wisdom of our predecessors while incorporating our innovations.

Secondly, there’s a saying: “A problem well defined is a problem half solved.”

By shedding light on the Core Productivity Blindspot, I hope to inspire enthusiasm for continuous improvement in knowledge work. That’s my aspiration, and it’s the reason for this article.

Lastly, we don’t need to resort to radical experimentation or start from scratch.

Specialization, experimentation, and standardization have proven effective for ages. We simply aren’t utilizing them enough in knowledge work. We can change that. It’s like playing poker—we haven’t yet played our strongest hand.

To implement these tried-and-true practices, we don’t need to invest hundreds of hours redesigning our productivity systems from the ground up.

Instead, we can adopt a few straightforward habits to gain momentum, gradually adding more as we progress:

- Specialization: Identify your unique strengths where you excel, enjoy your work, and perform at a higher level than others. Then, focus relentlessly on that area. Over time, strive to align your efforts more closely with your strengths.

- Experimentation: Rather than maintaining just a to-do list, create a list of improvements. As you progress through your day, aim to implement one small enhancement to each task you undertake. For instance, after a meeting, reflect on how you could have improved it. After a work session, consider how you might increase energy levels, reduce distractions, prioritize better, minimize errors, or enhance quality.

- Standardization: Establish your quality standards. Ensure that everything you produce meets these standards. When an error arises, pause your current task, investigate the root cause, and rectify it immediately.

Implementing these changes is crucial…

How 50x Productivity Will Transform Your Life and Impact the World

When we achieved a 50x productivity increase among manual workers in the 20th century, the average person’s standard of living surged. We transitioned from a world lacking electricity and plumbing to our current reality, complete with cars, planes, computers, and the Internet.

Moreover, the average manual worker’s hours shrank from 68 to 38 per week.

If we can replicate a 50x increase in knowledge work productivity and distribute the benefits fairly across society, we can usher in a new golden age. The outcomes are foreseeable:

- A 30-hour workweek, or even less, could become commonplace.

- Living standards would rise for everyone.

- Class conflicts would diminish as resources expand.

- Global poverty could be eradicated.

- And much more that we can’t yet envision.

When we significantly enhance our productivity, we often receive promotions and higher salaries (while sometimes having the option to work less). We will no longer have to bear the metaphorical wheelbarrow.

That is a future worth striving for.

There’s a well-known saying: “Where there’s a will, there’s a way.” The converse is equally valid. We have discovered the way; now we simply need to muster the will.

This article was crafted with dedication and care using the blockbuster mental model. If you wish to create your own blockbuster article (covering research, ideation, packaging, and writing), I offer a comprehensive year-long training program that I lead personally. To learn more, please fill out this application.

Note: If there are links to Amazon books, they are affiliate links, meaning I earn a small commission when you purchase the book. This compensation does not influence my recommendations; I only endorse books that I have read and genuinely appreciate.