Innovative 3D Printing Inspired by Bone Structures for Durability

Written on

Chapter 1: Introduction to Bone-Inspired Design

Every individual is likely to endure a bone fracture at some point in their life, yet it’s remarkable how resilient our bones are under pressure. A collaborative effort by scientists from Cornell University, Purdue University, and Case Western Reserve University has led to the creation of 3D-printed structures that mimic the durability of bone. This advancement could revolutionize high-stakes sectors such as construction and aerospace engineering.

In traditional 3D printing, solid structures are not entirely filled; instead, various “infills” are strategically employed to enhance strength. Similarly, bones derive their resilience from a spongy internal architecture known as trabeculae. The essence lies in the arrangement of beams and columns that distribute stress effectively. The research team discovered that by 3D printing modified versions of the “beams” found in human bones, they could achieve significantly stronger objects.

Section 1.1: Understanding Trabeculae

Trabeculae are composed of vertical plate-like struts and horizontal rod-like elements, functioning like columns and beams. In youth, bones are densely packed with these supportive structures, but this density diminishes with age, increasing the likelihood of fractures among older adults. The researchers sought to evaluate the impact of these trabecular structures on overall strength.

Subsection 1.1.1: Key Findings on Strength and Durability

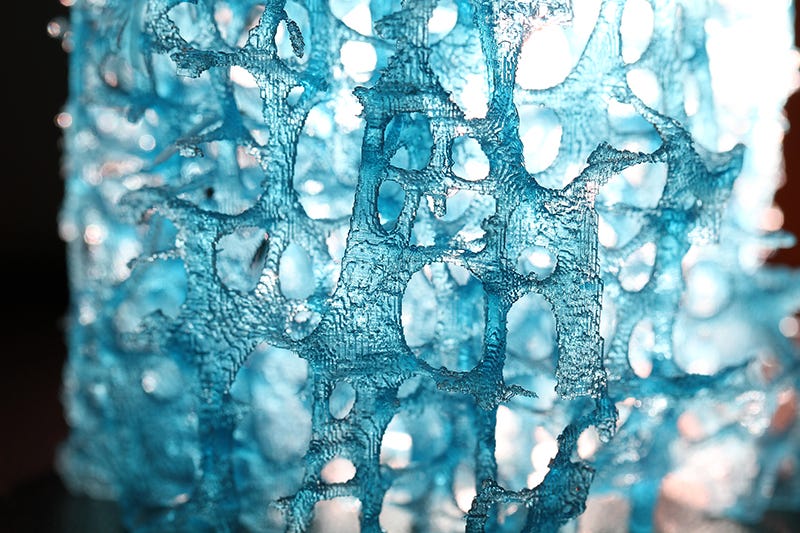

The team hypothesized that while the vertical plates contribute to the stiffness of bones, it is primarily the horizontal beams that ensure long-term durability. To illustrate this, they constructed a 3D-printed model of trabeculae (as shown below). The results indicated that the mechanical properties of these 3D-printed trabeculae closely resembled those of real bone. Following this, they developed a fully synthetic structure inspired by human bone and varied the thickness of the horizontal beams. Their findings revealed that increasing the beam thickness by 30% led to a staggering 100-fold enhancement in load-bearing capacity, underscoring the critical role of these horizontal supports in providing strength.

Section 1.2: Practical Applications of Bone-Inspired Structures

Enhancing the thickness of horizontal supports did not significantly add to the weight of the 3D-printed items. This discovery opens up possibilities for producing large, lightweight, and durable 3D-printed structures suitable for transportation. Such advancements could potentially reinforce habitats on Mars and deepen our understanding of age-related changes in bones, leading to new preventative treatments for fractures.

Chapter 2: Exploring Future Implications

The first video titled "Bone-Inspired Architectured Materials" delves into the innovative materials inspired by bone structures, highlighting their applications in various fields.

The second video, "How To 3D Print Bones? - A Future Bit From The Medical Futurist," explores the future of 3D printing in medicine, focusing on bone printing techniques.